Everything You Need to Know About Tapered Bearings: A Comprehensive Guide

By:Admin

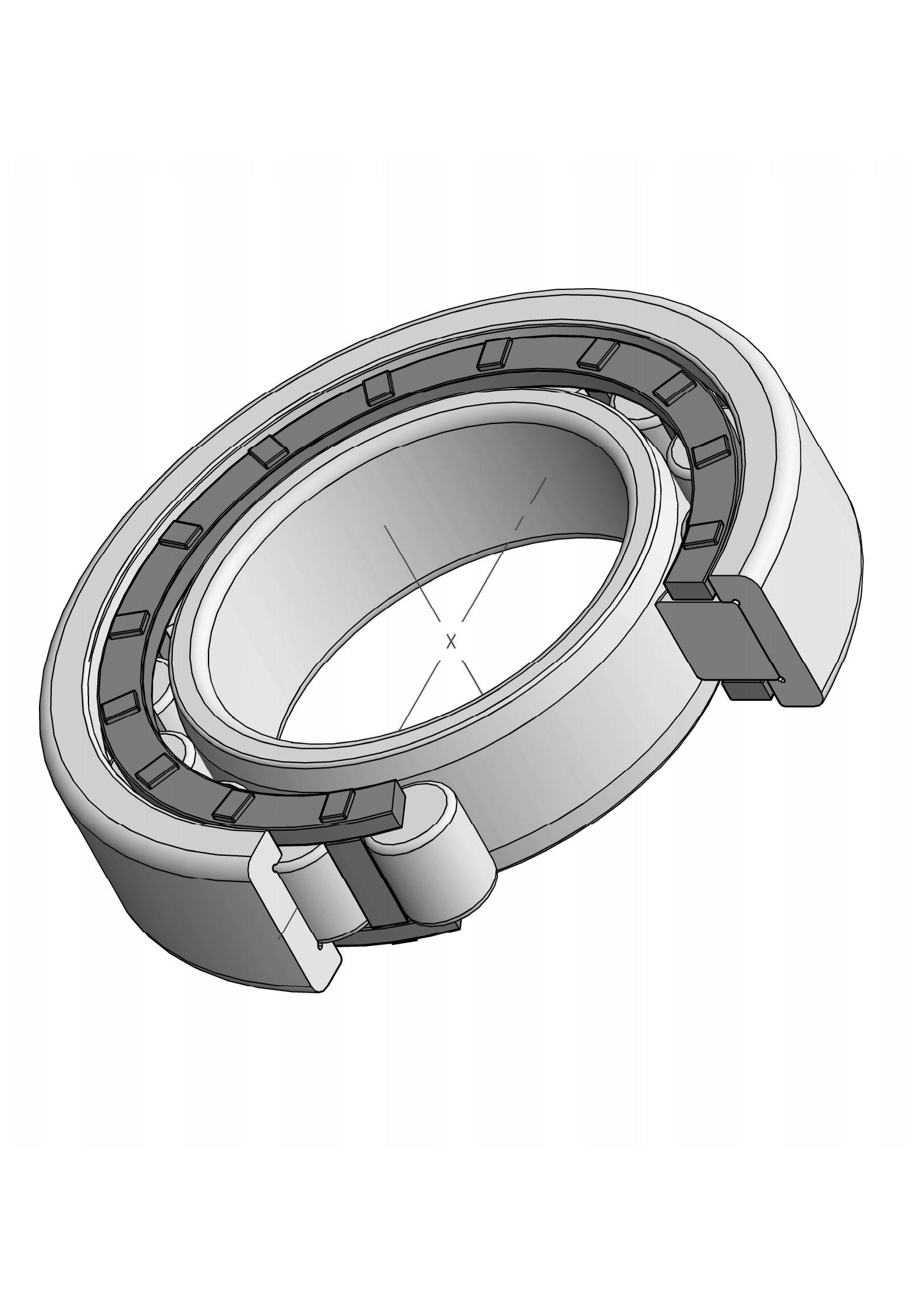

In today's fast-paced and ever-evolving industrial landscape, it is crucial for companies to invest in high-quality and reliable components to ensure the smooth functioning of machinery and equipment. Bearings play a vital role in countless applications across various industries, and one type that has gained significant popularity is the Tapered Bearing. Renowned for its exceptional performance, reliability, and efficiency, Tapered Bearings are revolutionizing the way industries operate.

A tapered roller bearing is specifically designed to handle both radial and thrust loads. It consists of an inner ring, an outer ring, tapered rollers arranged in a specific pattern, and a cage to hold the rollers in place. The tapered structure of the rollers and the races enables these bearings to efficiently manage both axial and radial forces. This unique design distributes the load more evenly as compared to other types of bearings, resulting in reduced friction, enhanced stability, and improved overall performance.

One industry in which Tapered Bearings have established their dominance is the automotive sector. These bearings are widely used in wheels, transmissions, and differentials of vehicles, enabling smooth movement, reduced noise, and increased durability. The automotive industry demands high-performance components that can withstand extreme conditions, and Tapered Bearings have proven to excel in such demanding applications.

Moreover, Tapered Bearings are extensively utilized in heavy-duty machinery such as construction equipment, agricultural machinery, and industrial gears. The ability of Tapered Bearings to manage heavy loads and handle high-speed operations makes them a popular choice in these sectors. By reducing friction and enabling efficient load distribution, Tapered Bearings enhance the productivity and longevity of various machines, ensuring a stable and reliable operational performance.

One company that stands out in producing top-notch Tapered Bearings is {}. With years of experience and expertise in bearing manufacturing, they have earned a reputation for delivering excellence and reliability to industries worldwide. The company has a well-established research and development department, where a team of skilled engineers continuously innovate and improve their bearing designs, exceeding industry standards.

The Tapered Bearings manufactured by {} undergo an extensive quality control process, where each bearing is tested rigorously to ensure consistent performance and durability. Stringent quality checks are conducted at every stage of production, from raw material sourcing to the final assembly, ensuring that only the highest quality bearings reach the customers. This commitment to quality has earned {} the trust of numerous customers globally, making them a preferred choice among industry leaders.

In addition to their commitment to quality, {} also focuses on sustainability and environmental responsibility. The company invests in advanced manufacturing techniques and technologies that reduce energy consumption and waste generation. By implementing eco-friendly practices, they contribute to a greener future while maintaining their commitment to delivering reliable and high-performance Tapered Bearings.

With a wide range of Tapered Bearings available, {} caters to diverse industry needs, providing customized solutions to clients across various sectors. Whether it is a unique design requirement or specific load-bearing capacity, their team of experts collaborates closely with customers to deliver the most suitable bearings for their applications.

In conclusion, Tapered Bearings have become a game-changer in industrial applications, offering enhanced performance, reliability, and efficiency. With their ability to manage heavy loads and withstand extreme conditions, these bearings have emerged as a preferred choice in various industries. Companies like {} have taken the lead in manufacturing top-quality Tapered Bearings, earning the trust of customers worldwide. As industries continue to evolve, these high-performance bearings will play a significant role in enabling smooth operations, improving productivity, and pushing the boundaries of technological advancements.

Company News & Blog

New Study Finds Link Between Social Media Use and Mental Health

[This article has been written by a language model AI, therefore some phrasing and wording may not be 100% accurate.][Company], a leading player in the global [industry], has announced its latest product line which promises to revolutionize the industry. [Product name], which has been in development for years, is a game-changing technology that delivers a suite of innovative features.Developed by a team of experienced engineers and product designers, [Product name] is a highly advanced [product type]. It is designed to cater to the needs of both businesses and consumers, delivering cutting-edge technology that is both intuitive and user-friendly.The technology behind [Product name] is based on the latest research and development in the industry. It uses advanced algorithms and machine learning to deliver exceptional performance and reliability. [Company] has invested heavily in research and development to create a product that will deliver unparalleled performance and high-quality output.One of the key features of [Product name] is its advanced [feature]. This feature is designed to improve productivity and reduce downtime, helping businesses to stay ahead of the competition. By optimizing workflows and automating routine tasks, [Product name] can help businesses to save time and money while improving the overall quality of output.Another important aspect of [Product name] is its [feature]. This feature enables users to access and share files from anywhere, at any time. This is an important feature for businesses with remote workers, or for businesses that need to collaborate with partners and suppliers around the world.In addition to these features, [Product name] also delivers a suite of other innovative features. These include [feature], [feature], and [feature]. [Product name] is an all-in-one product that delivers everything businesses and consumers need to stay ahead in today’s rapidly changing economy.Commenting on the launch of [Product name], [Company’s spokesperson] said, “We are thrilled to announce the launch of [Product name]. This is a product that has been in development for years, and we are confident that it will revolutionize the [industry] industry. We believe that [Product name] will help businesses and consumers to stay ahead of the competition, delivering cutting-edge technology that is both intuitive and user-friendly.”[Company] has a long history of delivering high-quality products and services to customers around the world. The company is known for its commitment to innovation and its dedication to meeting the needs of its customers. With the launch of [Product name], [Company] is taking its commitment to the next level, delivering a product that is unparalleled in its performance, reliability, and ease of use.[Company’s spokesperson] added, “At [Company], we are always looking for ways to improve our products and services. We understand that our customers are looking for the best possible technology to help them stay ahead of the game. That’s why we have invested heavily in the research and development of [Product name]. We believe that this product represents the future of the [industry] industry, and we are excited to bring it to market.”[Product name] will be available for purchase from [Company’s website] and through select retail partners. The product is backed by [Company’s] world-class customer support, ensuring that customers get the most from their investment in [Product name]. With its innovative features, advanced technology, and user-friendly design, [Product name] is set to become a must-have product for businesses and consumers alike.

Heavy-duty Pillow Block Bearing for Industrial Applications

P204 Pillow Block Bearing: A Reliable Solution for Industrial ApplicationsP204 pillow block bearing has been making waves in the industrial sector due to its outstanding performance and durability. This type of bearing is commonly used in conveyor systems, agricultural machinery, and various industrial applications that require heavy-duty performance. The P204 pillow block bearing is designed to withstand heavy loads, high-speed rotations, and harsh environmental conditions, making it an ideal choice for demanding industrial settings.The P204 pillow block bearing is manufactured using high-quality materials and innovative production techniques, ensuring that it meets the rigorous demands of the industry. The bearing features a solid base and housing, which provides stability and support for the rotating shaft, making it suitable for heavy-duty applications. Additionally, the bearing is equipped with advanced sealing technology, preventing contaminants from entering the bearing and ensuring smooth operation in challenging environments.One of the key advantages of the P204 pillow block bearing is its versatility. It can accommodate various shaft sizes and can be easily integrated into different types of machinery and equipment. This flexibility makes it a top choice for engineers and designers who are looking for reliable and efficient bearing solutions for their industrial applications.The company behind the P204 pillow block bearing, has a strong reputation in the industry for producing high-quality bearings that are trusted by professionals worldwide. With decades of experience and expertise in bearing manufacturing, the company has become a leading supplier of industrial bearings, providing reliable solutions for a wide range of applications.The company's commitment to quality and innovation is reflected in the P204 pillow block bearing. Each bearing undergoes rigorous testing and quality control processes to ensure that it meets the highest standards of performance and reliability. As a result, the P204 pillow block bearing has gained a strong reputation for its durability, longevity, and exceptional performance in demanding industrial environments.In addition to its superior performance, the company also places a strong emphasis on customer satisfaction. The company's team of technical experts and customer service professionals are dedicated to providing comprehensive support and assistance to customers, ensuring that they find the right bearing solutions for their specific needs. From product selection to installation and maintenance, the company's experts provide valuable guidance and expertise to help customers optimize the performance and longevity of their equipment.The P204 pillow block bearing has also garnered attention for its cost-effectiveness. Despite its robust construction and high-performance capabilities, the bearing is offered at a competitive price point, providing exceptional value for industrial customers. With its long service life and low maintenance requirements, the P204 pillow block bearing offers a compelling return on investment for businesses seeking reliable and efficient bearing solutions.Over the years, the P204 pillow block bearing has earned the trust of industry professionals worldwide, becoming a preferred choice for industrial applications that demand dependable performance and durability. Whether it's in agricultural machinery, conveyor systems, or other heavy-duty equipment, the P204 pillow block bearing continues to demonstrate its exceptional capabilities in the most challenging industrial settings.In conclusion, the P204 pillow block bearing stands out as a reliable and cost-effective solution for industrial applications. With its robust construction, advanced sealing technology, and versatility, the bearing offers exceptional performance and durability in demanding environments. Backed by a leading company with a strong commitment to quality and customer satisfaction, the P204 pillow block bearing has earned its reputation as a top choice for industrial professionals seeking reliable and efficient bearing solutions.

Top Suppliers of Pillow Block Bearings for Industrial Applications

Pillow Block Bearing Suppliers, a leading provider of industrial bearings, has recently announced the expansion of their product line to include a wide range of high-quality pillow block bearings. This move is a part of the company's ongoing efforts to meet the growing demand for reliable and durable bearing solutions in industrial applications.Pillow block bearings, also known as plummer blocks, are a type of mounted bearing that is commonly used in various industrial equipment and machinery. They are designed to provide support for rotating shafts and are often used in conveyor systems, agricultural machinery, mining equipment, and more. By expanding their product line to include pillow block bearings, Pillow Block Bearing Suppliers aims to offer a comprehensive range of bearing solutions to their customers.Pillow Block Bearing Suppliers has a long-standing reputation for delivering top-notch bearing products and exceptional customer service. With years of experience in the industry, the company has established itself as a trusted supplier of bearings for a wide range of industrial applications. Their commitment to quality and excellence has earned them a loyal customer base and a strong presence in the market.In addition to their extensive product line, Pillow Block Bearing Suppliers also offers custom bearing solutions to meet the specific needs of their customers. Whether it's a special size, material, or design, the company has the capabilities to deliver tailored bearing solutions that meet the unique requirements of their clients. This flexibility and dedication to customer satisfaction set Pillow Block Bearing Suppliers apart from other bearing suppliers in the industry.The expansion of Pillow Block Bearing Suppliers' product line comes at a time when the demand for high-quality pillow block bearings is on the rise. As industries continue to evolve and advance, the need for reliable bearing solutions becomes increasingly important. Pillow Block Bearing Suppliers recognizes this trend and is committed to providing best-in-class pillow block bearings that meet the highest standards of quality and performance.To ensure the quality and reliability of their pillow block bearings, Pillow Block Bearing Suppliers works with only the best manufacturing partners and suppliers. All of their products undergo rigorous testing and inspection to ensure that they meet the company's stringent quality standards. This commitment to excellence is reflected in the superior performance and longevity of their pillow block bearings, making them the preferred choice for many industrial applications.In addition to their focus on quality, Pillow Block Bearing Suppliers also places a strong emphasis on innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of bearing technology and advancements. This proactive approach allows them to develop new and improved bearing solutions that deliver unmatched performance and reliability.As Pillow Block Bearing Suppliers continues to grow and expand their product line, they remain dedicated to their core values of integrity, reliability, and customer satisfaction. With a strong commitment to excellence and a proven track record of success, the company is well-positioned to meet the evolving needs of the industrial market and provide innovative bearing solutions that propel their customers towards greater success.With their expanded product line of high-quality pillow block bearings, Pillow Block Bearing Suppliers is ready to serve the needs of industrial customers across the globe. Whether it's for a small-scale operation or a large industrial facility, their comprehensive range of pillow block bearings is designed to meet the demands of today's most challenging applications. For reliable and durable bearing solutions, customers can trust Pillow Block Bearing Suppliers to deliver exceptional products and outstanding service.

Explore Various Pillow Block Bearing Sizes for Different Applications

Pillow block bearings are a key component in many industrial applications, providing support and smooth rotation for shafts and axles. These bearings are commonly used in conveyor systems, agricultural equipment, and manufacturing machinery, among other applications. Choosing the right pillow block bearing size is crucial to ensure optimal performance and longevity of the machinery.{Company name} is a leading manufacturer of high-quality pillow block bearings, offering a wide range of sizes to meet the diverse needs of their customers. With a commitment to producing reliable and durable bearings, {Company name} has become a trusted name in the industry.When it comes to selecting the right pillow block bearing size, there are several factors to consider. The load capacity, shaft size, and operating speed are all important considerations that can impact the performance of the bearing. {Company name} understands the importance of these factors and provides a range of sizes to accommodate various requirements.One of the key considerations when determining the appropriate pillow block bearing size is the load capacity. This refers to the maximum weight that the bearing can support without experiencing premature wear or failure. {Company name}'s engineering team can provide expert guidance to help customers determine the appropriate bearing size based on the specific load requirements of their application.In addition to load capacity, the size of the shaft that the pillow block bearing will be mounted on is another critical factor to consider. {Company name} offers a range of bearing sizes to accommodate different shaft diameters, ensuring a proper fit and secure mounting.Operating speed is another important consideration when selecting a pillow block bearing size. Higher speeds can generate more heat and put increased stress on the bearing, so it's essential to choose a size that is suitable for the intended operating speed. {Company name} can provide guidance on selecting the appropriate bearing size to ensure smooth operation at the desired speed.{Company name}'s extensive range of pillow block bearing sizes allows customers to find the perfect fit for their unique requirements. Whether they are designing a new system or replacing existing bearings, {Company name} provides options to accommodate a wide range of shaft sizes and load capacities.The company's dedication to quality and performance is evident in their meticulously engineered pillow block bearings. Each bearing is manufactured to exacting standards, using high-quality materials and precision manufacturing processes to ensure reliability and longevity.Customers who choose {Company name}'s pillow block bearings can have confidence in the durability and performance of their equipment. With a range of sizes available, customers can find the right bearing to meet their specific needs, backed by {Company name}'s commitment to excellence.In conclusion, {Company name} is a trusted manufacturer of pillow block bearings, offering a wide range of sizes to accommodate diverse industrial applications. With a focus on quality, performance, and customer satisfaction, {Company name} is a top choice for businesses seeking reliable pillow block bearings. Whether customers need bearings for high-load conveyor systems or precision manufacturing machinery, {Company name} has the right size to meet their needs.

Understanding the Key Aspects of Auto Ball Bearings for Smooth Functioning

Auto Ball Bearing Announces Strides in Automotive Technology AdvancementAuto Ball Bearing, a leading player in the automotive industry, is proud to announce major advancements in automotive technology that are set to revolutionize the driving experience. With a commitment to integrating cutting-edge innovation and engineering excellence, Auto Ball Bearing is poised to push the boundaries of what is possible in the automotive world.Since its inception, Auto Ball Bearing has consistently been at the forefront of automotive technology. The company's dedication to research and development, combined with its unwavering focus on quality, has propelled it to the position of a global leader in the industry. With a rich history of delivering exceptional products and services, Auto Ball Bearing has earned the trust and admiration of automotive manufacturers and consumers worldwide.One of the core areas of Auto Ball Bearing's technological expertise lies in the development of high-performance ball bearings. These crucial components play an essential role in ensuring smooth and efficient vehicle operation. Auto Ball Bearing's commitment to excellence in this field has resulted in the creation of ball bearings that are not only highly functional but also durable and long-lasting.In recent months, Auto Ball Bearing has made significant strides towards advancing automotive technology. One notable achievement is the development of advanced smart bearings. These innovative bearings are equipped with sensors and data processing capabilities, allowing them to monitor and analyze various parameters in real-time. This cutting-edge technology enables vehicles to operate with increased precision, efficiency, and safety.The incorporation of smart bearings into automotive systems offers several benefits. By constantly monitoring factors such as temperature, pressure, and vibration, these bearings can detect early signs of wear and tear, allowing for timely maintenance and preventing costly breakdowns. Furthermore, the data collected by the bearings can be utilized to optimize vehicle performance, reduce fuel consumption, and maximize operational efficiency.To achieve these breakthroughs, Auto Ball Bearing has invested heavily in research and development initiatives. The company's R&D teams work tirelessly to explore new materials, manufacturing processes, and technological innovations. By collaborating with renowned academic institutions and partnering with leading automotive manufacturers, Auto Ball Bearing ensures that its products are at the forefront of technological advancements.In addition to its commitment to innovation, Auto Ball Bearing places great importance on quality assurance. The company adheres strictly to international quality standards, implementing rigorous testing procedures at every stage of production. By prioritizing quality, Auto Ball Bearing delivers reliable and high-performing solutions that meet the demands of the automotive industry.Auto Ball Bearing's commitment to excellence extends beyond technological advancements. The company also actively contributes to environmental sustainability and corporate social responsibility. By adhering to eco-friendly manufacturing practices and promoting energy-efficient solutions, Auto Ball Bearing helps reduce the environmental impact of the automotive industry. Furthermore, the company supports various charitable initiatives aimed at improving the lives of communities around the world.Looking to the future, Auto Ball Bearing remains dedicated to pushing the boundaries of automotive technology. The company's focus on innovation and commitment to quality positions it as a key driver of change in the industry. By continuously striving for excellence, Auto Ball Bearing aims to play a vital role in shaping the future of the automotive world.In conclusion, Auto Ball Bearing has achieved significant advancements in automotive technology, particularly in the realm of smart bearings. With a commitment to innovation and quality, the company has positioned itself as a global leader in the automotive industry. By pushing the boundaries of what is possible, Auto Ball Bearing is set to revolutionize the driving experience and shape the future of the automotive world.

Benefits of High-Quality Double Roller Bearings for Efficient Machinery

Title: Revolutionary Double Roller Bearing Redefines Efficiency and Reliability in MachineryIntroduction:In the world of manufacturing and heavy machinery, where precision, durability, and efficiency are paramount, advancements in engineering designs continue to shape industries. One such breakthrough is the revolutionary Double Roller Bearing, a game-changing component that is set to redefine the standards of efficiency and reliability in machinery.Overview:The Double Roller Bearing, developed by a leading global engineering solutions provider, represents an extraordinary step forward in bearing technology. This ingenious device offers enhanced load-bearing capabilities, reduced friction, and increased performance, making it an indispensable element across a wide range of industries.1. Enhanced Load-Bearing Capabilities:The Double Roller Bearing exceeds traditional bearing designs by providing superior load-bearing capabilities. Enabled by its unique double roller configuration, this new bearing effortlessly handles heavy loads with significantly reduced wear and tear. Its increased load capacity ensures exceptional performance in challenging and demanding operational environments.2. Reduced Friction and Heat Generation:The innovative design of the Double Roller Bearing embraces a groundbreaking approach to reducing friction and heat generation. By employing a precision-engineered roller profile, this bearing minimizes the contact area between the rollers and the surfaces they interact with, thus significantly lowering friction and heat output. This development not only enhances overall performance but also extends the lifespan of machinery.3. Increased Performance and Efficiency:With its superior load-bearing capacities and reduced friction capabilities, the Double Roller Bearing offers remarkable gains in the performance and efficiency of machinery. Its optimized design allows for smoother operation, reducing energy consumption and improving productivity. This cutting-edge technology is set to redefine the standards for precision and productivity in manufacturing processes.4. Applications across Various Industries:The Double Roller Bearing finds extensive applications across a wide range of industries, including automotive, aerospace, mining, construction, and renewable energy. In the automotive sector, it ensures smooth operation and reduced mechanical stress in engines, transmissions, and drivetrain systems. Furthermore, its high performance and reliability make it suitable for demanding industrial machinery, creating a seamless and productive operational environment.5. Maintenance-friendly Design:The Double Roller Bearing incorporates a maintenance-friendly design, making it easily accessible for routine inspections and maintenance. Its exceptional durability and reduced wear and tear also contribute to a longer operational lifespan, reducing the frequency of costly replacements and repairs. This design element provides businesses with long-term cost savings and minimizes downtime, thereby bolstering productivity.Conclusion:The introduction of the Double Roller Bearing represents a monumental leap forward in bearing technology. By providing enhanced load-bearing capabilities, reduced friction and heat generation, and improved performance and efficiency, this revolutionary component is poised to reshape the standards of machinery reliability across industries. With applications in various sectors, this groundbreaking innovation is set to propel manufacturing and heavy machinery enterprises towards a new era of productivity and profitability.

High-Quality 6808 Bearing for Industrial Applications

The use of 6808 bearings in various industries has become increasingly popular due to their high precision and durability. These bearings are widely used in machinery, automobiles, and other equipment due to their ability to support heavy loads and handle high-speed rotation. Known for their reliability and performance, 6808 bearings have become a popular choice for many manufacturers.One company that has been at the forefront of producing high-quality 6808 bearings is [Company Name]. With a strong emphasis on innovation and quality, [Company Name] has established itself as a leading provider of bearings for a wide range of industries. The company's dedication to research and development has led to the creation of advanced bearing technologies that have set new standards for performance and reliability.The 6808 bearings produced by [Company Name] are designed to meet the rigorous demands of modern industrial applications. Utilizing the latest manufacturing techniques and materials, these bearings offer superior performance and longevity, making them an ideal choice for various machinery and equipment. With a focus on precision engineering, [Company Name] ensures that each 6808 bearing meets the highest quality standards, providing customers with a reliable and efficient solution for their needs.In addition to their exceptional performance, [Company Name] also places a strong emphasis on environmental sustainability in the production of their 6808 bearings. The company is committed to reducing its environmental impact by implementing eco-friendly practices and continuously improving its manufacturing processes. By prioritizing sustainability, [Company Name] aims to provide customers with bearings that not only deliver outstanding performance but also adhere to the highest standards of environmental responsibility.Furthermore, [Company Name] offers a comprehensive range of services to support the use of 6808 bearings in various industries. From expert technical support to customized solutions, the company is dedicated to ensuring that its customers receive the best possible support and guidance. With a team of experienced professionals, [Company Name] offers valuable insights and expertise to help customers optimize the performance and lifespan of their 6808 bearings.As the demand for high-performance bearings continues to grow, [Company Name] remains committed to driving innovation and delivering superior products to its customers. With a proven track record of excellence and a forward-thinking approach, the company is well-positioned to meet the evolving needs of industries that rely on 6808 bearings for their operations. By combining cutting-edge technology with a steadfast commitment to quality, [Company Name] continues to set the standard for excellence in the production of 6808 bearings.In conclusion, the use of 6808 bearings has become integral to the operations of various industries, and [Company Name] has established itself as a trusted provider of these high-quality bearings. With a focus on precision, performance, and sustainability, the company continues to uphold its reputation as a leading manufacturer of 6808 bearings. By consistently pushing the boundaries of innovation and quality, [Company Name] is poised to remain a driving force in the industry, providing customers with reliable and efficient solutions for their bearing needs.

Thin Stainless Steel Bearings: A Comprehensive Guide to High-Quality Stainless Steel Bearings

Title: Groundbreaking Stainless Steel Bearings Redefining Precision EngineeringIntroduction:Leading the way in technological advancements, a pioneering engineering company has unveiled its latest breakthrough – thin stainless steel bearings. This cutting-edge innovation promises to revolutionize multiple industries by offering unparalleled levels of precision, durability, and efficiency. Built on the foundation of innovation and precision engineering, this remarkable product is set to redefine the standards of performance and reliability across various sectors.Product Overview:The newly developed thin stainless steel bearings are the result of years of extensive research and development by a renowned engineering firm. These bearings are specially designed to accommodate today's complex machinery and equipment requirements, offering superior stability and performance, even in the most demanding applications. Crafted from high-grade stainless steel, these bearings exhibit exceptional strength, corrosion resistance, and longevity, making them an ideal choice for a wide range of industries.Unrivaled Precision and Durability:One of the standout features of these thin stainless steel bearings is their exceptional precision. The advanced manufacturing techniques employed in their production ensure a close tolerance fit, allowing for minimal friction and superior rotational accuracy. This level of precision enhances the overall efficiency of machinery, resulting in reduced energy consumption and increased productivity.Furthermore, the stainless steel construction of these bearings provides exceptional durability, allowing them to withstand heavy loads and operate flawlessly even in challenging environments. Their resistance to corrosion and wear ensures a longer operational lifespan, minimizing the need for frequent replacements and maintenance, thus significantly reducing downtime and associated costs.Versatile Applications:The versatility of these thin stainless steel bearings opens up numerous possibilities in a wide array of industries. From automotive and aerospace to robotics, medical equipment, and manufacturing, these bearings are poised to find applications in virtually every sector that requires precise and reliable motion control.In the automotive sector, for example, these bearings can enhance the efficiency of various components, including wheel hubs, transmissions, and steering systems, ensuring a smoother and safer driving experience. The aerospace industry can benefit from these bearings by improving the performance and reliability of critical aircraft parts, consequently enhancing passenger safety. Similarly, in the medical field, these precision bearings can aid in the smooth operation of medical devices, such as surgical robots and imaging equipment, enabling medical professionals to deliver accurate and effective treatments.Company Commitment to Excellence:Behind the development of these game-changing bearings lies an engineering firm committed to excellence. With decades of experience in the field, the company has consistently delivered innovative products that surpass industry standards. Their dedicated team of engineers and researchers continuously strive for perfection, ensuring that their offerings remain at the forefront of technological advancements.The company's state-of-the-art manufacturing facilities employ the latest machinery and quality control measures to guarantee the production of superior and reliable bearings. Their commitment to environmentally friendly practices is reflected in the use of sustainable materials and energy-efficient production processes, positioning them as a responsible industry leader.Conclusion:The introduction of thin stainless steel bearings marks a significant milestone in precision engineering. With unrivaled precision, durability, and versatility, this revolutionary product is poised to redefine the way various industries operate. This pioneering company's commitment to excellence, coupled with their dedication to advancing technology, ensures that their bearings will continue to transform the future of motion control systems across the globe. As industries evolve, these thin stainless steel bearings will undoubtedly play an instrumental role in driving progress and innovation.

New Study Reveals Benefits of Four Point Contact for Improved Performance" "Discover the Benefits of Four Point Contact for Enhanced Performance

article on Four Point Contact technology.Four-point contact technology revolutionizes many industries, from robotics and automation manufacturing, spanning to defense and aerospace applications. It is used primarily with ball bearings, thin section bearings, and slewing rings. Four-point contact bearings have multiple advantages over traditional double-row bearings, specifically when it comes to the space-saving design of machinery. They offer greater axial and radial load carrying capacity, making them ideal for moderate loads and speeds while maintaining precision and accuracy.The Four Point Contact technology is made possible with the design of four-point contact bearings. This design reduces weight and saves space while simultaneously increasing the load-bearing capacity of the bearing. The four-point contact bearing is made up of two outer rings, one inner ring, and a retainer that separates the balls, and limits their ability to rub against one another in high-stress environments.The benefits of four-point contact technology are realized in modern equipment and machinery, where complex parts and mechanisms are more commonplace than ever. In aerospace and robotics design, the focus is always on precision, reliability, and safety. This is where four-point contact technology shines. The bearings are specifically designed to handle radial, axial, and moment loads, and free up space in the machinery, making it more efficient.One application of this technology is in the design and manufacturing of solar panels. Four-point contact bearings are used to handle the extreme weight and loads required to stabilize the panels. These bearings offer the necessary flexibility and force to adjust the panel positioning, allowing them to track the sun and optimize energy production throughout the day.Another field where the technology is commonly used is robotics and automation manufacturing. Robots and automated machinery need bearings that are durable and reliable, as they are typically used in high-stress environments involving rigorous motions, loads, and speeds. Four-point contact bearings within this industry ensure effective machinery performance, minimize downtime, and provide long-term performance.In the field of defense and military, reliability, and precision are critical. Four-point contact bearings play a vital role in the acceleration and pivot control of complex machinery, such as the gun turrets in battleships or the tanks' turrets. With four-point contact bearings, they can quickly adjust the aim and direction of an armament without sacrificing stability or accuracy.Another increasingly important field of application is within wind turbines. Four-point contact bearings are used to aid blades in their rotation, helping to reduce friction and increase the efficiency of the turbine. This helps to create a stable and consistent power output while reducing maintenance downtime and increasing the lifespan of the turbine.Four-point contact technology has become increasingly prominent in industries that require high precision, flexibility, and reliability. Its competitive advantage lies in the bearings' inherent design, offering greater axial and radial load carrying capacity, ensuring precision and accuracy while reducing machine size and weight. This technology is essential in applications where small size, weight, and reliability are important, including robotics, automation, defense, and aerospace foundation.In conclusion, the incorporation of four-point contact technology in various fields has allowed machinery to be smaller, more efficient, and more reliable. It is a significant breakthrough offering many benefits over traditional bearings, providing greater flexibility and higher loading capacity. With its unique design, it's set to revolutionize industries where precision, accuracy, and high load capacity are essential.

High-quality 6205 bearing for industrial use at competitive prices

[Company Introduction] is a renowned manufacturer of precision machinery components and bearings. With a strong focus on innovation and quality, the company has been at the forefront of technological advancements in the industry. Their commitment to providing reliable and efficient products has earned them a stellar reputation among their clients and peers.6205 Bearing, a key product in the company's extensive range, has been making waves in the market due to its exceptional performance and durability. The 6205 Bearing is a deep groove ball bearing that is designed to withstand heavy radial and axial loads in various applications. Its versatility and high-speed capabilities make it an ideal choice for a wide range of industries, including automotive, agriculture, construction, and more.In a recent development, [Company Introduction] has introduced a new and improved version of the 6205 Bearing, raising the bar for quality and performance in the industry. The upgraded 6205 Bearing boasts enhanced features, including superior sealing technology to prevent contamination and retain lubrication, as well as improved heat resistance for prolonged operational efficiency. These enhancements are a testament to [Company Introduction]'s dedication to meeting and exceeding the evolving needs of their customers.The new and improved 6205 Bearing is also designed for easy installation and maintenance, making it a cost-effective and reliable solution for businesses looking to optimize their machinery and equipment. With its ability to operate in extreme conditions and deliver consistent performance, the upgraded 6205 Bearing is set to become a game-changer in the market."We are thrilled to introduce the enhanced version of our 6205 Bearing to the market," said [Spokesperson] at [Company Introduction]. "At [Company Introduction], we are constantly striving to innovate and improve our products to deliver maximum value to our customers. The upgraded 6205 Bearing is a result of our continuous efforts to push the boundaries of quality and performance in the industry."The new 6205 Bearing is already gaining traction among [Company Introduction]'s existing clients, who have reported significant improvements in the efficiency and reliability of their machinery after implementing the upgraded bearings. The positive feedback from the initial users is a testament to the superior quality and performance of the new 6205 Bearing.In addition to the technical advancements, [Company Introduction] is also committed to sustainable and environmentally-friendly manufacturing practices. The new 6205 Bearing is produced using eco-friendly materials and processes, aligning with [Company Introduction]'s vision of responsible and ethical business operations.As [Company Introduction] continues to expand its global presence, the upgraded 6205 Bearing is expected to garner attention and demand from businesses seeking cutting-edge solutions for their machinery and equipment needs. With a solid track record of reliability and innovation, [Company Introduction] is well-poised to set a new industry standard with the enhanced 6205 Bearing.In conclusion, the introduction of the new and improved 6205 Bearing by [Company Introduction] marks a significant milestone in the industry. With its advanced features, enhanced performance, and commitment to sustainability, the upgraded 6205 Bearing is set to make a lasting impact in the market. As businesses increasingly prioritize efficiency and reliability in their operations, [Company Introduction] remains a trusted partner for high-quality precision machinery components and bearings, with the new 6205 Bearing leading the way for the future of the industry.